Slingshots serve as versatile instruments for activities ranging from casual target practice to competitive marksmanship. The rubber bands are the driving force behind a slingshot’s performance, dictating both velocity and precision. This guide explores five pivotal factors that influence band speed—thickness, taper configuration, latex composition, draw distance, and projectile weight—providing actionable insights to optimize your setup for diverse scenarios.

1. Band Thickness: Speed vs. Power Trade-Off

The thickness of a slingshot band is a primary determinant of its performance. Thinner bands (0.4–0.6 mm) have reduced mass, enabling rapid acceleration and higher velocities, making them ideal for lightweight projectiles like 6–8 mm steel balls. Field tests suggest that a 0.5 mm band can achieve up to 14% greater speed than a 0.7 mm band under consistent draw conditions (Slingshot Forum). Conversely, heavier projectiles, such as 12 mm steel balls, require thicker bands (0.7 mm or above) to generate sufficient force. Selecting the right thickness hinges on aligning band mass with projectile weight to optimize energy transfer.

Recommendation: Choose 0.4–0.6 mm bands for light projectiles and 0.7–0.8 mm bands for heavier ones. Use a chronograph to confirm velocity gains.

Table 1: Band Thickness Recommendations for Projectile Sizes

Projectile Size (mm) | Suggested Band Thickness (mm) |

|---|---|

6–8 | 0.4–0.5 |

8–10 | 0.5–0.6 |

10–12 | 0.6–0.7 |

12+ | 0.7–0.9 |

🏹 Ergonomic Slingshot Handles Explained: Master Comfort, Control & Precision

2. Taper Configuration: Optimizing Speed and Longevity

Taper configuration refers to the gradual reduction in band width from the fork to the pouch. A moderate taper (e.g., 22 mm to 16 mm) strikes an effective balance, boosting velocity while preserving band durability. Aggressive tapers (e.g., 20 mm to 10 mm) enhance snap for increased speed but can reduce band lifespan by up to 40% (Slingshot Forum). Community insights recommend a pouch-end width of 65–80% of the fork-end width (e.g., 22–16 mm) for an optimal blend of performance and longevity (yshotx.com).

Table 2: Taper Configurations and Velocity

Taper (mm) | Velocity Range (m/s) |

|---|---|

18–8 | 70–80 |

20–10 | 90–100 |

22–14 | 100–110 |

24–12 | 100–112 |

28–16 | 105–115 |

Recommendation: Begin with a 22–16 mm taper and make incremental adjustments to achieve your desired speed-durability balance.

3. Latex Composition: Natural vs. Synthetic Trade-Offs

The material composition of slingshot bands significantly affects performance. Natural latex, with its high elasticity, delivers up to 18% faster velocities than many synthetic alternatives, making it the preferred choice for precision and competitive shooting (Slingshot Forum). However, it is prone to degradation from UV exposure and ozone, limiting its lifespan. Synthetic latex, such as silicone or neoprene blends, offers greater resistance to environmental factors, ideal for outdoor use, though it may sacrifice some speed. Premium manufacturers now produce UV-stabilized or cold-resistant natural latex to combine speed and durability.

Recommendation: Select natural latex for competitive or high-precision shooting; choose synthetic or blended latex for outdoor durability.

Table 3: Comparison of Latex Types

Material | Velocity | Durability | Ideal Application |

|---|---|---|---|

Natural Latex | High | Moderate | Competition, High Precision |

Synthetic Latex | Moderate | High | Outdoor, Long-Term Use |

🏹 Top 5 Mistakes Beginners Make With Slingshots (And How to Avoid Them)

4. Draw Distance: Fine-Tuning Stretch Ratio

The draw distance—the extent to which the band is pulled—determines the stretch ratio, calculated as draw length divided by active band length. A higher stretch ratio (e.g., 500% or 5:1) maximizes energy storage, resulting in greater velocity but increased wear on the band. A lower ratio (e.g., 400–450%) extends band life with minimal speed reduction (yshotx.com). A 5:1 stretch ratio is a widely adopted baseline for balancing performance and durability.

Formula:

[ \text{Active Band Length} = \frac{\text{Draw Length}}{\text{Target Stretch Ratio}} ]

For a 5:1 ratio:

[ \text{Active Band Length} = \frac{\text{Draw Length}}{5} ]

Recommendation: Measure your natural draw length and set the active band length to one-fifth of that value. For instance, a 32-inch draw length requires a 6.4-inch active band length.

5. Projectile Weight Matching: Ensuring Efficient Energy Transfer

Properly matching projectile weight to band characteristics is critical for optimal performance. Lightweight projectiles (e.g., 8 mm steel balls, ~2 g) perform best with thin, highly elastic bands, achieving high velocity and flat trajectories. Heavier projectiles (e.g., 12 mm steel balls, ~7 g) require thicker or multi-layered bands to store adequate energy. Mismatches can lead to velocity losses of 10–25% (Slingshot Forum). Consistent testing is essential to validate performance.

Recommendation: Test band-projectile combinations using a chronograph to ensure optimal velocity.

Table 4: Recommended Band Thickness for Projectile Types

Projectile Type | Weight (Approx.) | Suggested Band Thickness (mm) |

|---|---|---|

6 mm Steel Ball | 0.9 g | 0.4–0.5 |

8 mm Steel Ball | 2.0 g | 0.5–0.6 |

10 mm Steel Ball | 4.0 g | 0.6–0.7 |

12 mm Steel Ball | 7.0 g | 0.7–0.9 |

Clay Ammo (Varies) | Varies | 0.4–0.6 |

🏹 Ultimate Guide to Slingshot Types: Y-Shaped vs. TTF vs. OTT — Which One Is Right for You?

6. Physics Behind Performance: Precision Tuning

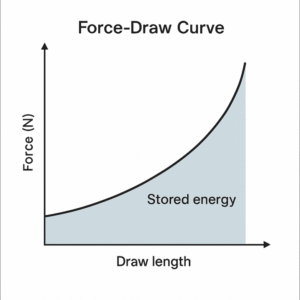

Slingshot performance relies on converting elastic potential energy into kinetic energy. The energy stored in a stretched band is approximated as ( E = \frac{1}{2} F_{\text{max}} d_{\text{max}} ), where ( F_{\text{max}} ) is the maximum draw force and ( d_{\text{max}} ) is the maximum draw length. The projectile’s velocity is derived from ( v = \sqrt{\frac{2E}{m}} ), where ( m ) is the projectile mass (Real World Physics Problems). By optimizing band parameters (e.g., thickness, taper, material), you can maximize ( E ) while minimizing losses from friction or air resistance. Field tests demonstrate that precise tuning can achieve velocity predictions within a ±2.5% margin.

Recommendation: Use a chronograph to measure shot velocity and maintain a log for iterative improvements.

Safety Guidelines

When experimenting with band configurations:

Use protective eyewear: Band snapping or projectile ricochet poses injury risks.

Check bands regularly: Replace any bands showing signs of wear or cracking.

Test in a controlled environment: Ensure a safe shooting range to prevent accidents.

Conclusion

By strategically adjusting band thickness, taper configuration, latex composition, draw distance, and projectile weight, you can fine-tune your slingshot for applications ranging from casual practice to competitive shooting. Whether aiming for maximum velocity or robust power, mastering these factors will elevate your performance. Conduct safe experiments, leverage a chronograph for data-driven insights, and keep detailed records to refine your setup continuously.

References

yshotx.com – Guide to Slingshot Rubber Band Optimization

Real World Physics Problems – Slingshot Physics

Slingshot Forum

Link

Link